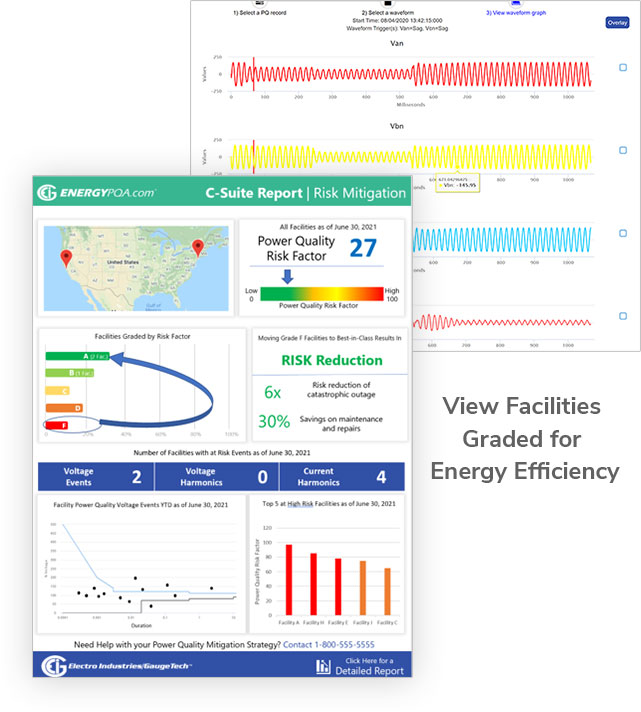

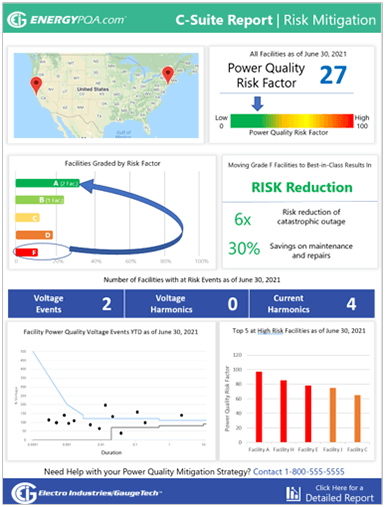

Identify the Least Reliable Facilities and Circuits to Improve Power Quality

An essential aspect of industrial energy reliability is power quality. Power quality events can cause damage to factory equipment, downtime, safety issues, and lost productivity and revenue. An estimated 20-40% of downtime is power quality related and 80% of power quality issues originate within facilities. Prevent downtime by identifying the highest risk facilities and circuits with the worst power quality using EIG’s AI driven EnergyPQA.com® cloud-based energy management system and power quality meters. The EnergyPQA.com® system gives deep insights into power quality in all metered areas of the factory.

- View dashboards showing voltage power quality, voltage and current faults, THD, waveform recordings, and power factor, including CBEMA and SEMI F47 graphs.

- Automatically grade facilities on best-to-worst power quality risk.

- Identify specific circuits in the worst facilities to provide simple meaningful actions that improve reliability and safety of the power system.

View Power Quality Risk Factors

for All Facilities

Respond Proactively to Power Quality Problems Before They Become Critical

EIG’s power quality meters and EnergyPQA.com® energy management system send email alerts for programmed alarm limits and for all power quality events.

- Send email alerts to multiple recipients.

- Emails contain a link to the event details in the EnergyPQA.com® system.

- Take remedial action before problems have escalated to the point of power or equipment failure.

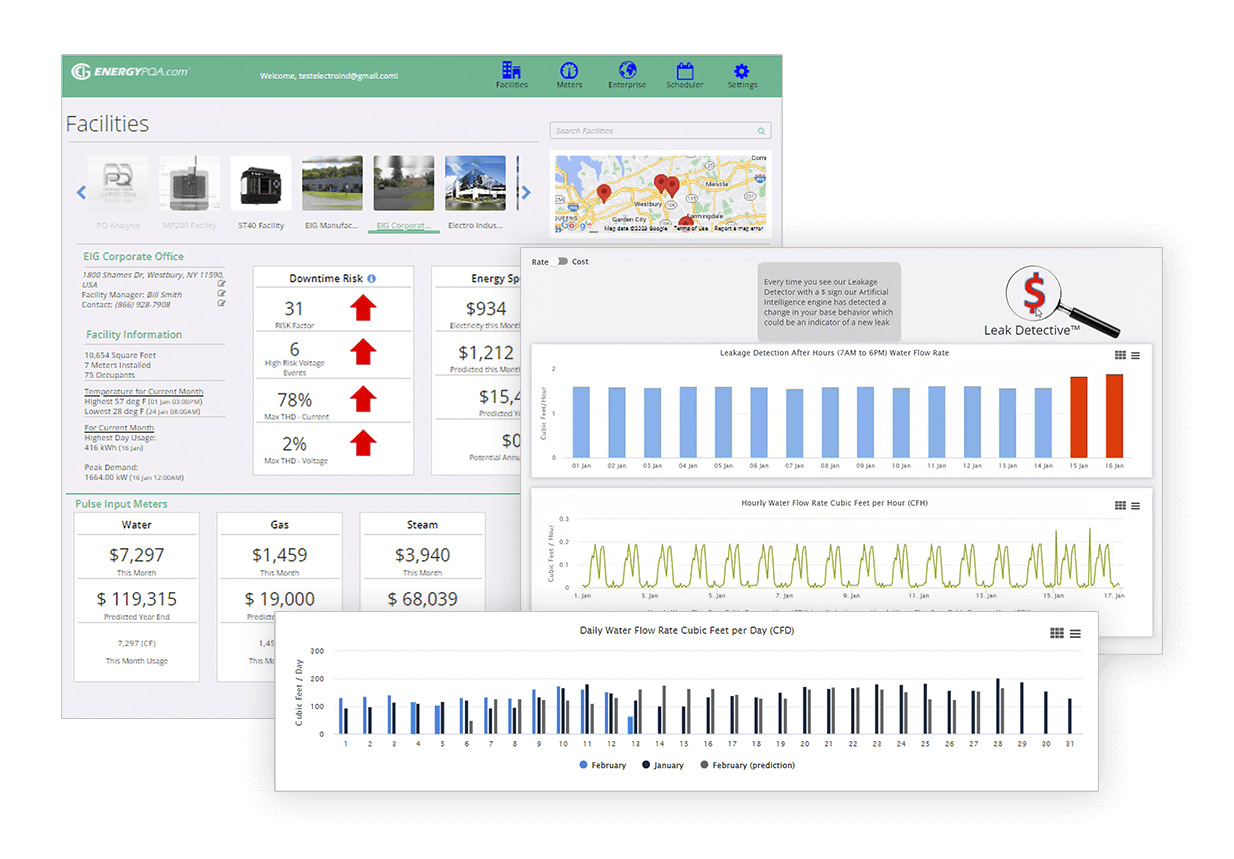

Manage All Commodity Usage

The EnergyPQA.com® system allows you to track all commodity usage in one place, eliminating the need for discrete systems for water, air, gas, electric, and steam (W.A.G.E.S.) usage. View detailed usage and commodity cost dashboards. Trend commodity usage within a building and compare use between factory buildings. With the unique Leak Detective™ feature, be alerted to air and water leaks, allowing timely action to save resources and money. Generate reports for all W.A.G.E.S. commodity usage.

W.A.G.E.S. Dashboard

Identify Wasteful Facilities and Circuits to Improve Energy Efficiency

According to the U.S Department of Energy, factories and industrial plants account for a third of U.S. energy use and 20% of that usage can be saved by reducing energy waste. Energy efficient facilities can consume up to 85% less power. The EnergyPQA.com® energy management system transforms traditional energy management by identifying the most energy wasteful facilities and circuits to maximize energy efficiency improvements.

- Automatically grade facilities and circuits for energy efficiency using smart analytics.

- Identify potential savings by improving least efficient facilities and circuits.

- Improve energy management for industrial applications by focusing on facility circuits most in need of improvement.

View Facilities and Circuit Grading with

Potential Cost Savings

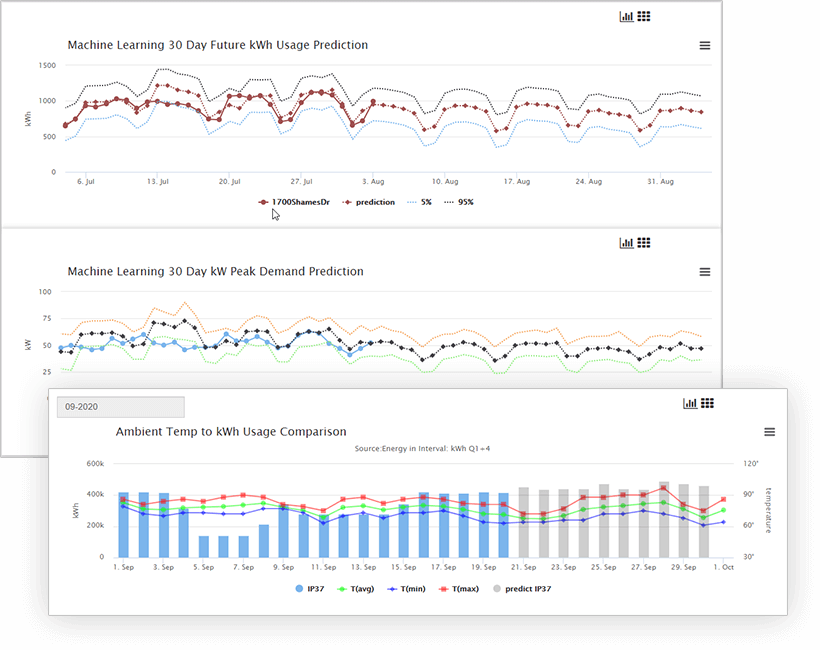

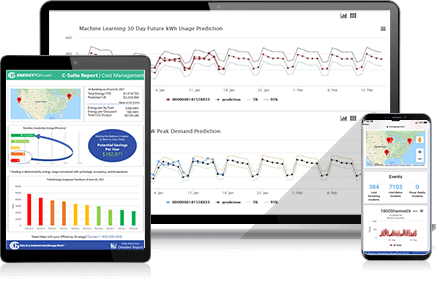

Reduce Costs with AI-based Predictions

Use the EnergyPQA.com® energy management system’s AI-based energy predictions to provide insights into factory energy trends into the future. By looking at future predictions, a facility manager can then be proactive to make sure that energy reduction programs are successful. The system uses historical energy readings and future weather forecasts to provide usage and demand before they occur.

- Accurately predict demand and energy usage into the future with advanced AI and machine learning.

- Take action on peak demand predictions in advance of penalty.

- View energy dashboards that detail energy usage and demand across factory areas and provide insightful predictive analysis.

The system emails notifications of new predicted peak demand up to three days in advance. Since demand charges can be as high as 50% of a factory’s actual energy bill, this information can yield significant savings. Use the EnergyPQA.com® energy management system’s predictive energy usage dashboards to determine the success of demand mitigation efforts.

Use Artificial Intelligence to Predict

Energy Usage into the Future

Make Factory Energy Usage Reliable, Efficient, and Cost Effective

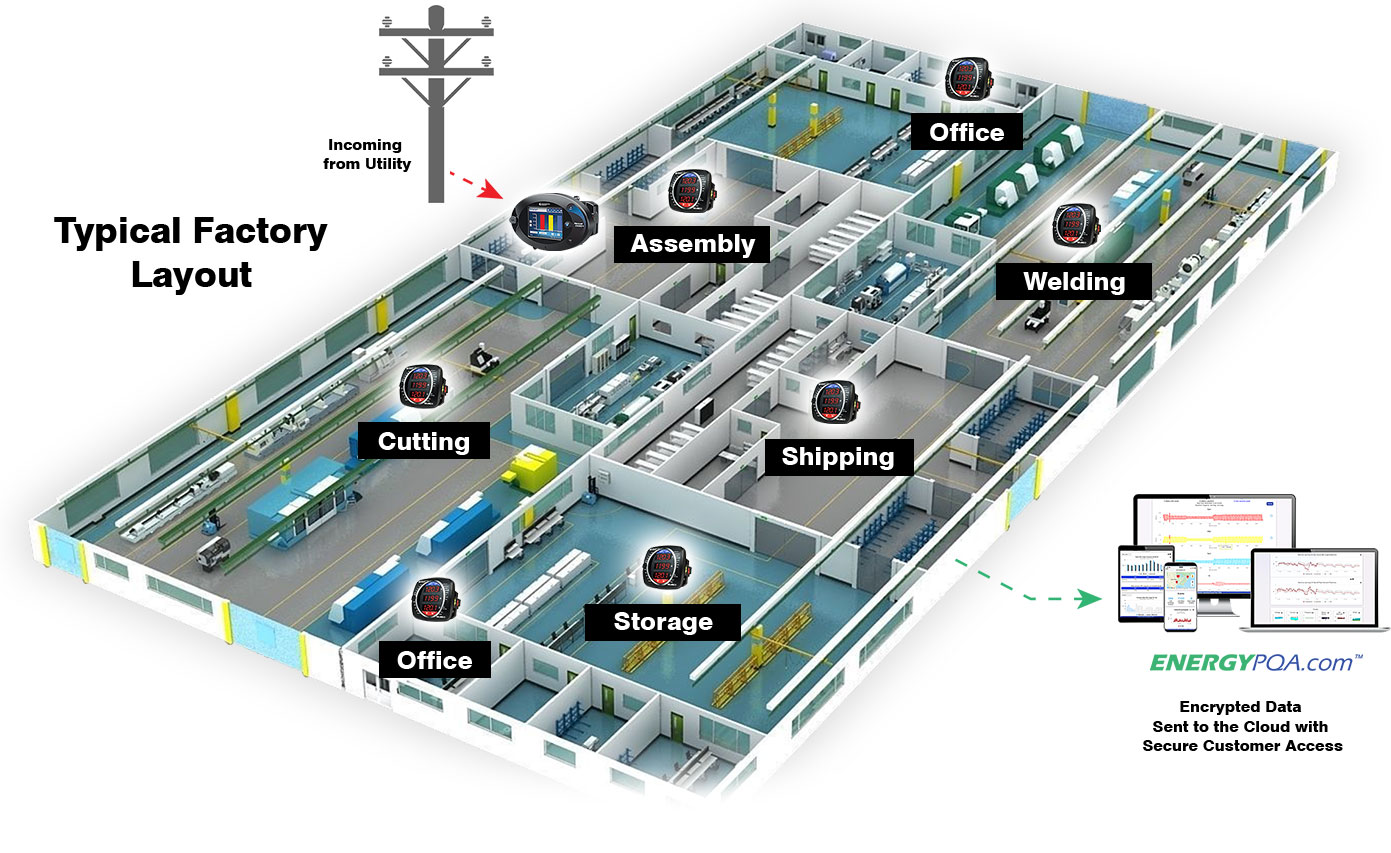

Submetering produces accurate cost allocation that results in energy savings of up to 18%. Use EIG meters and the EnergyPQA.com® energy management system to provide energy awareness and change the mindset of tenants and energy users. Install meters at all needed locations to conserve energy through actual energy usage billing rather than square footage estimates.

Popular Products for Energy Management in Industrial Applications

Cloud-Based Energy Management Solution

reducing costs, and improving power system reliability

Cloud-Based Energy Management Solution

Critical Load Point

Critical Load Point

Large Loads (400 A or more)

Large Loads (400 A or more)

Smaller Loads (200 A or less, high-density)

Smaller Loads (200 A or less, high-density)

Engineering Services

Engineering Services

Other Related Products

https://www.electroind.com/eigs-energypqa-com-cloud-solution-is-finalist-in-plant-engineerings-2020-product-of-the-year/

https://www.electroind.com/eig-releases-energypqa-com-cloud-based-energy-management-solution/

https://www.electroind.com/facts-you-should-know-about-commercial-energy-waste-in-2019/

https://www.youtube.com/watch?v=XTiIsF1D0Fc

https://www.youtube.com/watch?v=GAVJERWMKeU