Power Quality Metering Solutions

What are the Challenges to Power Quality?

Challenge 1: Poor Power System Reliability

Up to $39 billion dollars is lost each year due to power interruptions. Poor power reliability, including voltage surges and sags, have a direct impact on enterprise operational efficiency. This in turn has the effect of reducing profitability.

Solution: Monitor Power Quality to Reduce Downtime

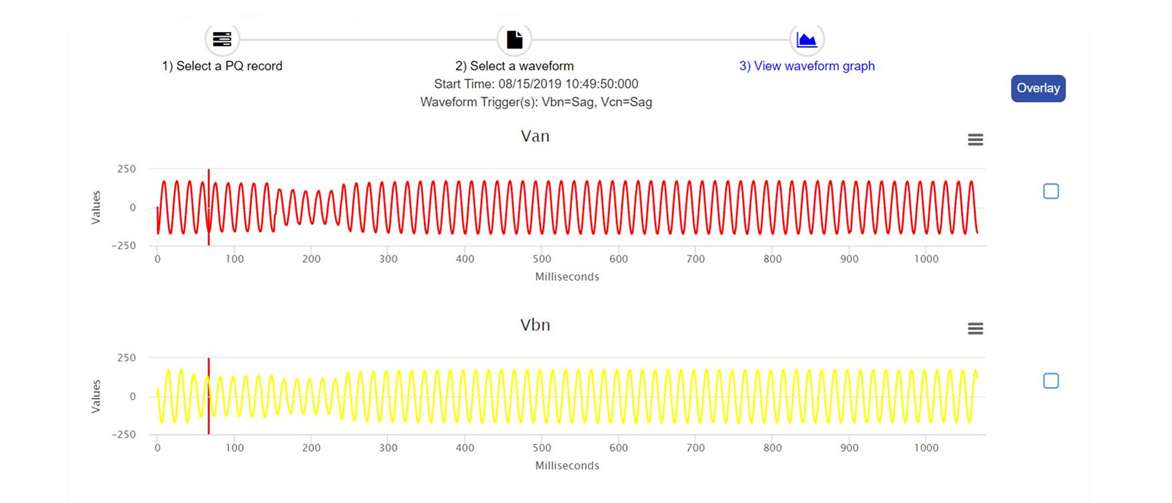

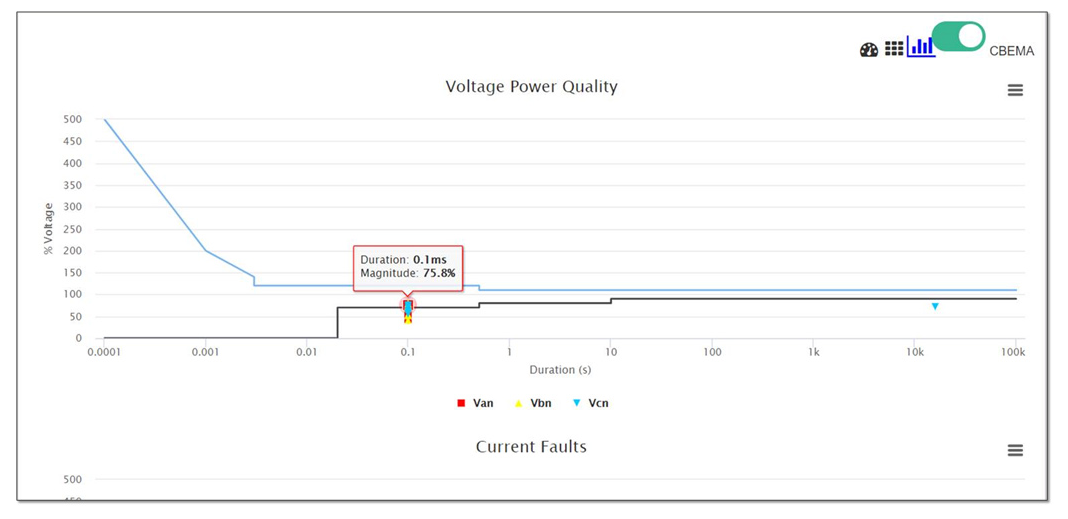

Voltage sags can be particularly problematic for modern microprocessor-based equipment. Specially true as the ride-through time on power supplies also continues to decrease. A sag lasting longer than three cycles can cause problems with sensitive equipment such as servers, protective equipment, process controllers, and other types of microprocessor-based devices. These and other “smart” devices may experience intermittent lockups or corrupted data when voltage sags occur.

Nexus® series power quality meters analyze the power system health throughout an enterprise. They measure and record voltage surges, sags and allow users to understand the source of poor power quality conditions. Without this information, it is almost impossible to pinpoint the cause of voltage disruptions or equipment failure.

Moreover, Nexus® series power quality meters send out alarm emails in real time, giving immediate notification of outages or other power quality problems. And like EIG’s EnergyPQA.com® cloud solution collects all power quality data and generates reports on hidden threats that affect the reliability and health of the power system and the equipment connected to it.

Challenge 2: Poor Power Factor Reduces System Efficiency

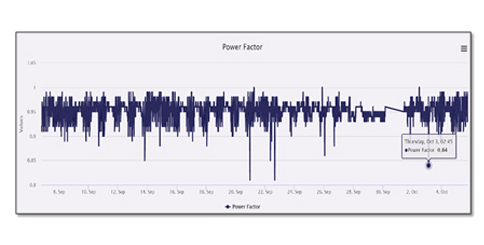

Power Factor is the ratio of the real power absorbed by the load to the apparent power flowing in the circuit. A machine with a low power factor draws more current than a machine with a higher power factor (closer to 1) for the same number of Watts. Poor power factor causes a higher amount of current for the same power draw. Higher currents increase the energy lost in the distribution system, and require larger wires, higher rated transformers, and other equipment. Poor power factor can also result in damage to equipment as well as higher energy usage and resultant coasts. In many jurisdictions, utilities penalize customers for excessive power factor.

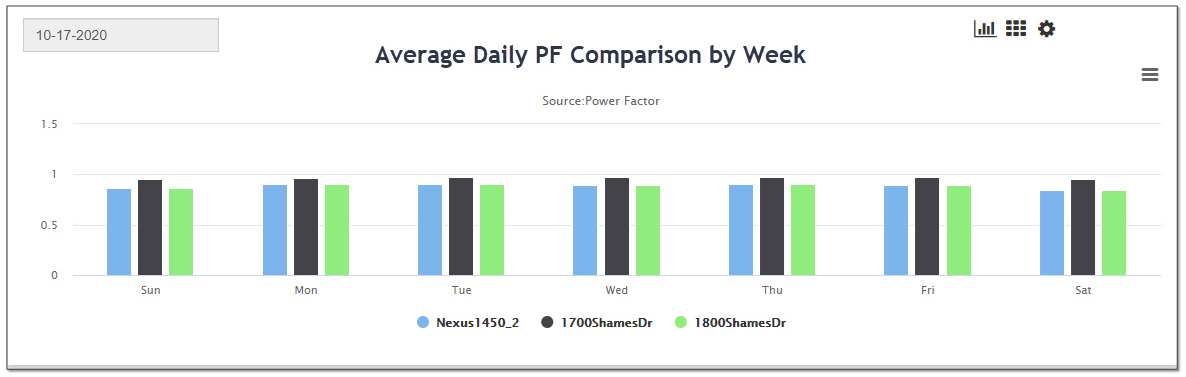

Solution: Collect Data to Correct Worst Case Scenarios

To counteract hidden power factor problems, it is important to monitor the electrical circuits feeding loads. Nexus® series power quality meters monitor, trend, and alarm on power factor. With EnergyPQA.com®, the user can generate enterprise-level reports showing the poorest power factor at any facility. This allows a user to isolate the least efficient equipment for replacement or correction. The benefits of correcting power factor include improving voltage stability, reducing unnecessary energy usage, reducing lines losses, and eliminating transformer and wiring upgrades. Moreover, if the user is in a jurisdiction with power factor penalties, these surcharges will also be reduced.

Challenge 3: Harmonics Generated By Non-Linear Load Technology

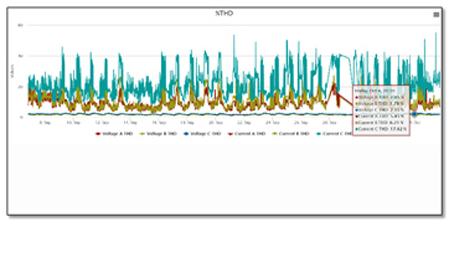

In an electrical power system, a harmonic is a voltage or current at a multiple of the fundamental frequency. The harmonic is generally produced by non-linear loads. Harmonics in power systems result in increased heating in the equipment and conductors. They are a very common problem in electrical power systems. It is important to identify and mitigate these harmonics.

Solution:

Nexus® series power quality meters monitor both voltage and current harmonics throughout the power system. Metering these harmonics allows users to identify high harmonic conditions. These conditions are typically caused by servers, printers, fluorescent lighting, variable frequency drives, soft starters, and other equipment. The Nexus® series power quality meters measure harmonics to the 128th order. They have extensive logging that can trend the individual harmonics. Additionally, they can provide emails on excessive and critical harmonic conditions.

Products

https://www.electroind.com/nexus-1500p-advanced-programming-webinar/

https://www.electroind.com/eig-releases-color-touchscreen-external-display-for-nexus-1450-meter/

https://www.wfmz.com/news/pr_newswire/pr_newswire_technology/eig-releases-energypqa-com-tm-cloud-based-energy-management-solution/article_1b9444d9-2379-5c37-8e3d-cfd0c734fc89.html

https://www.youtube.com/watch?v=biecA80Jwj4

https://www.utilityproducts.com/test-measurement/article/14178057/eig-releases-energypqacom-cloud-based-energy-management-solution