Introduction

Implement a Customizable SCADA Application to Manage and Optimize Energy Usage

Energy is one of a factory’s biggest expenses. Managing energy usage is therefore an important aspect of reducing costs and maximizing profits. Additionally, maintaining high power quality is essential to any industrial facility. Industry studies show that up to 40% of all downtime is power quality related, 80% of these issues originate within the facility, and 50% of mission critical power outages are due to power quality issues. Downtime results in significant economic loss for a factory.

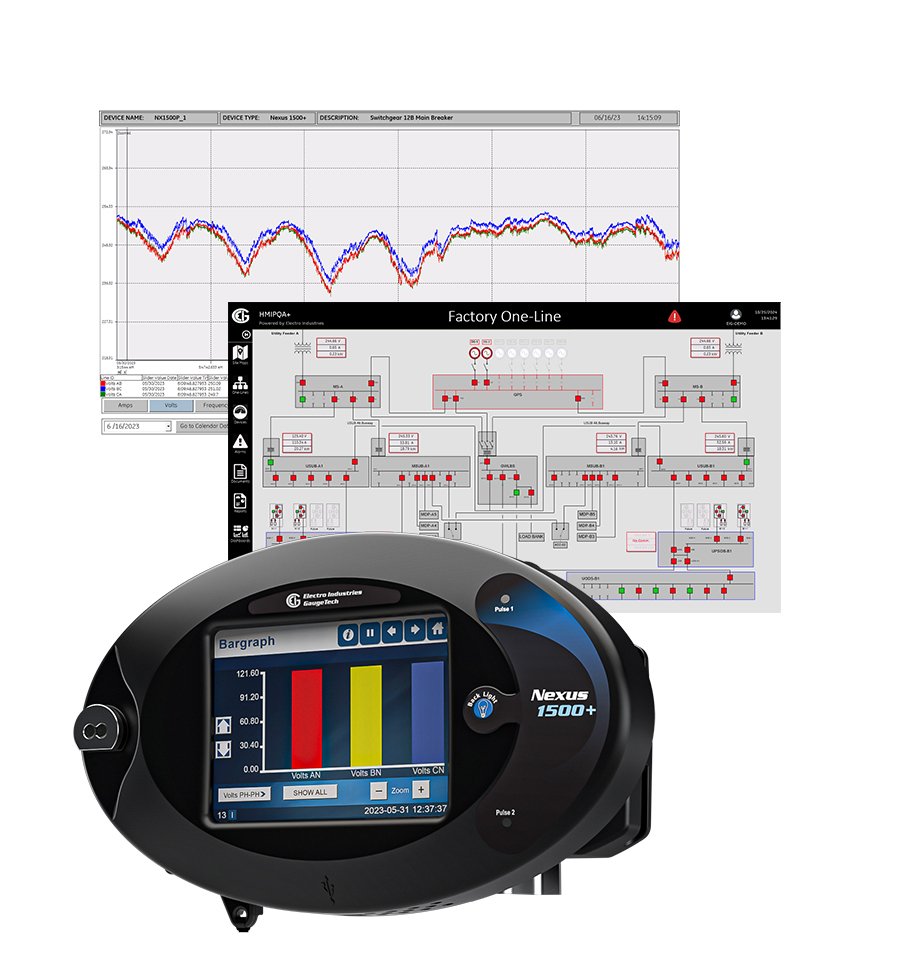

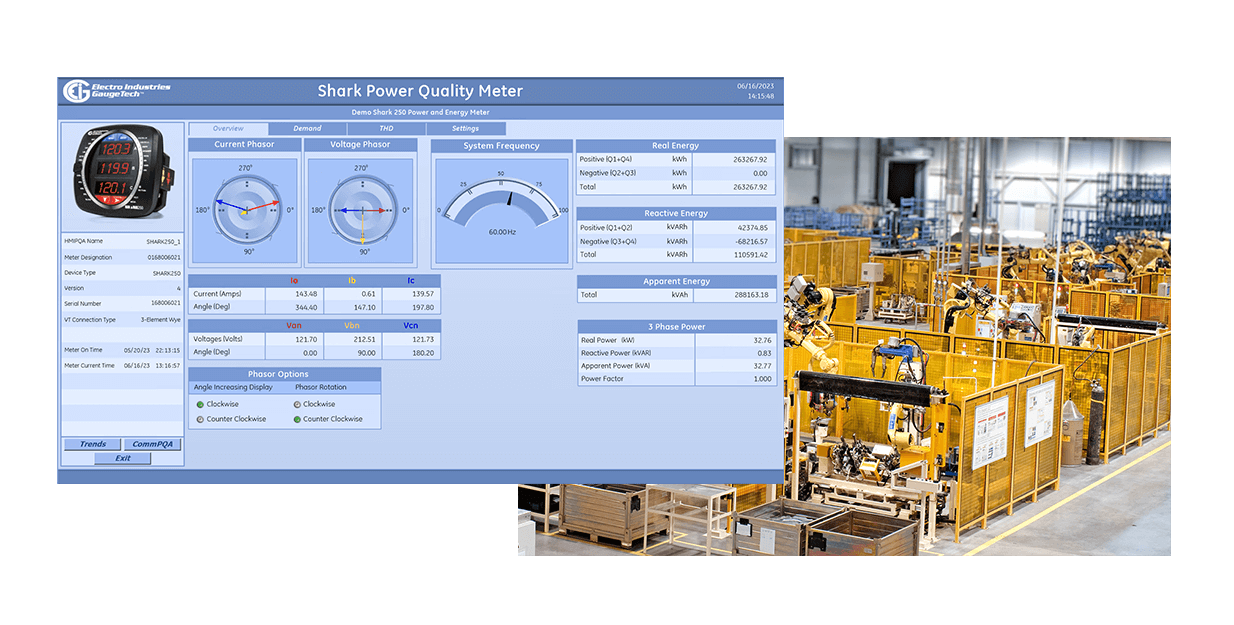

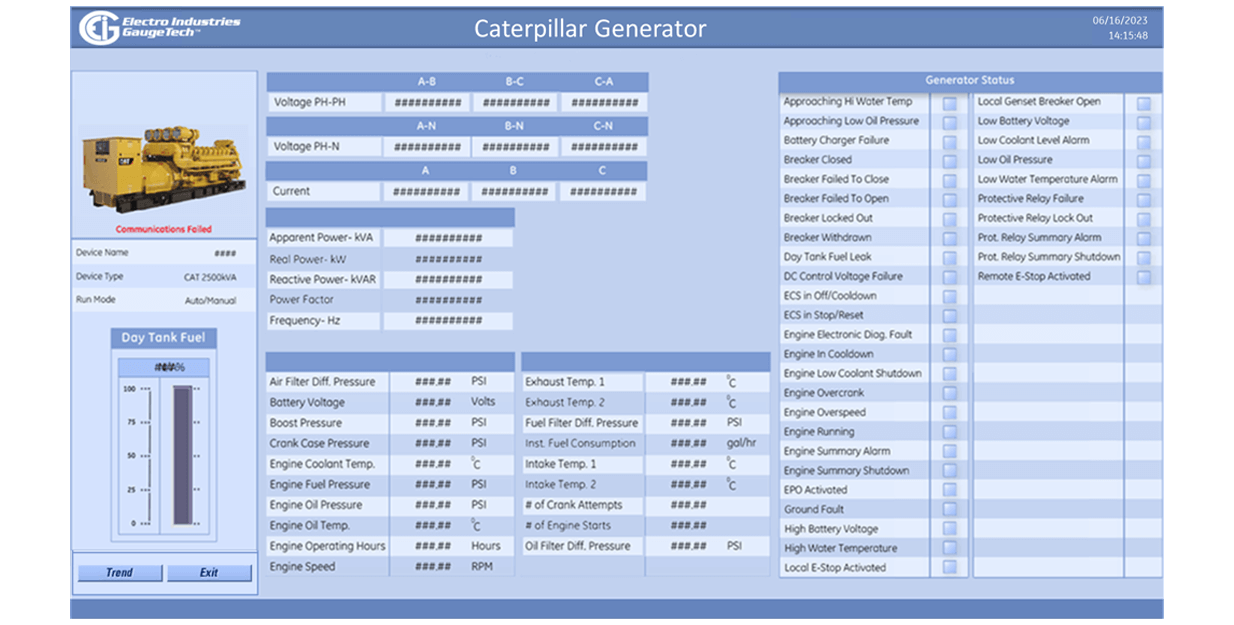

EIG’s power and energy meters have advanced power quality monitoring features. When paired with EIG’s energy management software – the HMIPQA+™ SCADA application and the EnergyPQA.com® AI driven energy management system, industrial facilities gain multiple ways to proactively identify potential power issues and optimize energy usage, reducing downtime, extending equipment lifespan, and improving overall operational efficiency. Implementing a SCADA application that is customized to a specific factory’s needs allows facility managers to track their energy usage in all areas of the facility and to take action when problems are indicated.

|

|

Respond Proactively to Power Quality Problems Before They Become Critical

HMIPQA+™ SCADA and the EnergyPQA.com® system provide solutions that allow factory managers to pinpoint and address power quality problems before they cause critical disruptions. EIG’s power quality meters and energy management applications send email alerts for programmed alarm limits and for all power quality events.

- Send email alerts to multiple recipients. Emails contain a link to the event details in the EnergyPQA.com® system.

- HMIPQA+™ dashboards and alarms notify operators of power quality problems.

- Take remedial action before problems have escalated to the point of power or equipment failure.

- Perform detailed power quality analytics on data from EIG’s advanced power quality meters.

Power Quality Information

Real Time Monitoring of Critical Assets

Equipment Protection

A factory’s successful work depends on its equipment remaining in good condition. By monitoring energy usage and power quality in all parts of the factory, the HMIPQA+™ SCADA solution enables operators to view real time conditions and be immediately alerted to any problems with their critical equipment. Having this information in one central location enables early detection of issues, so that facility managers can perform preventative maintenance before failures occur or expensive equipment is damaged. The HMIPQA+™ application supports multiple third party devices and protocols that enable it to interface with existing equipment management systems.

Identify Wasteful Facilities and Circuits to Improve Energy Efficiency

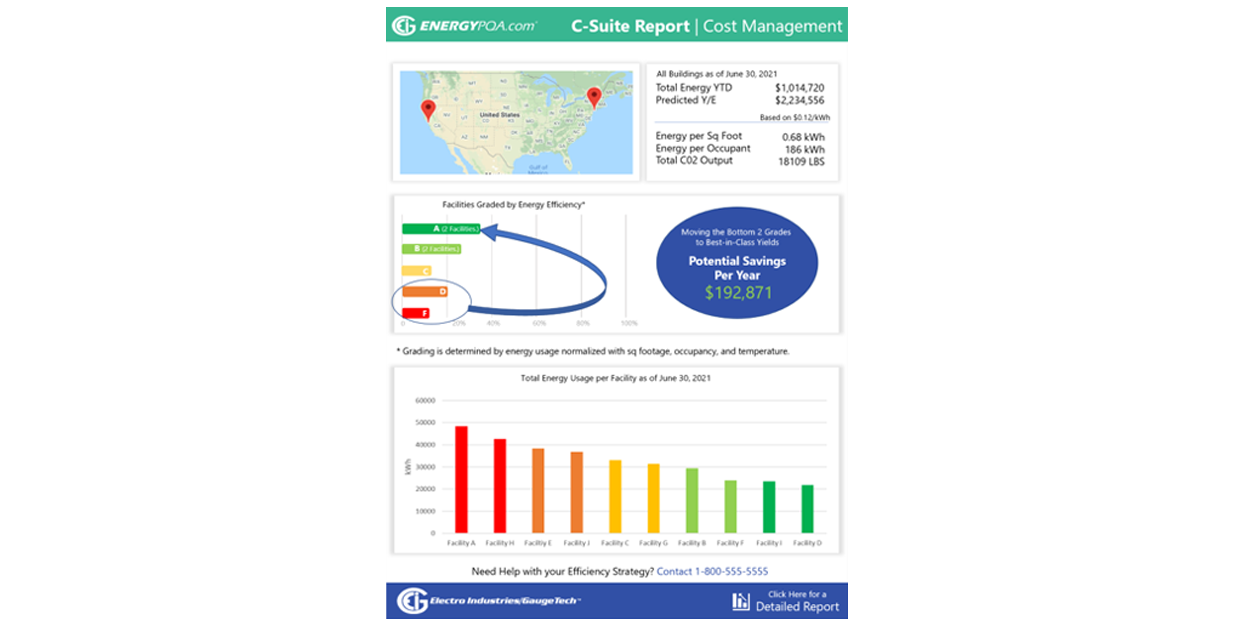

According to the U.S Department of Energy, factories and industrial plants account for a third of U.S. energy use and 20% of that usage can be saved by reducing energy waste. Energy efficient facilities can consume up to 85% less power. Employing the data from EIG’s power and energy meters, the EnergyPQA.com® energy management system transforms traditional energy management by identifying the most energy wasteful facilities and circuits to maximize energy efficiency improvements.

- Automatically grade facilities and circuits for energy efficiency using smart analytics.

- Identify potential savings by improving least efficient facilities and circuits.

- Focus on facility circuits most in need of improvement.

View Facility and Circuit Grading with Potential Cost Savings

Products

Industrial Products

Nexus® 1500+ Advanced Power Quality Meter | |

|---|---|

| Critical Load PointExample Installation: Utility Entry Points, Critical Loads, High Power Sensitivity Points |

Shark® 250 Cyber Secure Power and Energy Meter | |

|---|---|

| Large Loads (400 A or more)Example Installation: Typical Building Loads, Substations, Control Panels |

MP200™ Multipoint Metering System (8 Three Phase Meters) | |

|---|---|

| Smaller Loads (200 A or more)Example Installation Smaller Panel Boards, High-density Circuits |

EnergyPQA.com® AI Driven Energy Management System | |

|---|---|

| Provides energy analytics and predictions, reducing costs and improving power system reliabilityOrdering Part #: ENERGYPQA-1Y |

HMIPQA+™ Next Generation SCADA Solution | |

|---|---|

| Simple, scalable, fully customizable application with open connectivity and multi-protocol supportOrdering Part #: Contact EIG_sales@hubbell.com. |

Downloads

https://www.electroind.com/eigs-energypqa-com-cloud-solution-is-finalist-in-plant-engineerings-2020-product-of-the-year/

https://www.electroind.com/eig-releases-energypqa-com-cloud-based-energy-management-solution/

https://www.electroind.com/facts-you-should-know-about-commercial-energy-waste-in-2019/

https://www.youtube.com/watch?v=XTiIsF1D0Fc

https://www.youtube.com/watch?v=GAVJERWMKeU